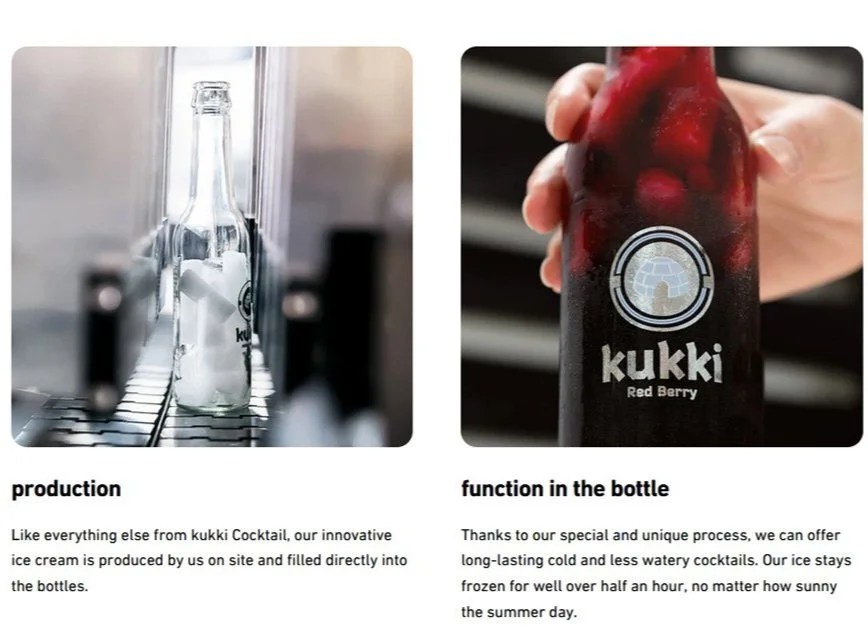

Eight references were combined to reject this slick process for serving up prepackaged ice-cold beverages with ice already in the bottle. According to their website, the applicant Kukki Cocktail (www.kukkicocktail.com/) markets unique “long-lasting cold and less watery cocktails” where the ice “stays frozen for well over half an hour, no matter how sunny the summer day.” With summer approaching, the appeal is clear.

The case is appeal 2024-000660, application 16/063,918. Claim 1 on appeal is reproduced below (emphasis added for the primarily disputed limitation on appeal). For context, the invention here requires a specific order of operations (that were claimed) in terms of how the ice and other ingredients are added and cooled so as to achieve a desired effect upon finally serving the drink.

1. A method for producing and storing a beverage in a beverage container and preparing the beverage for consumption, comprising the following steps:

providing a beverage container, which is to be filled; introducing a cooling agent in the beverage container through a container opening, wherein the cooling agent comprises at least one water ice molding, the water ice molding drops to and directly contacts a bottom of the beverage container and the bottom of the beverage container has a temperature higher than 0°C and thus melts the water ice molding on the outside creating a water film between the water ice molding and the bottom of the beverage container;

filling the beverage container with a beverage liquid through the container opening after the cooling agent is introduced in the beverage container, wherein the beverage liquid differs from the cooling agent and the temperature of the beverage liquid is maintained lower than 0°C during the filling of the beverage container such that the beverage liquid freezes the water film and the water ice molding adheres to the bottom of the beverage container and does not float in the beverage liquid when the beverage liquid is added;

closing the beverage container opening by means of a disposable closure after filling the beverage container with the beverage liquid; and

cooled storing of the filled beverage container; wherein the beverage container comprises a container section which tapers towards the container opening and which is closed by means of a disposable closure; the cooling agent comprising the at least one water ice molding and the beverage liquid are introduced through the tapering container section after passing the container opening, and the at least one water ice molding in one spatial dimension is larger than a diameter of the container opening, wherein during the cooled storing, the filled beverage container is cooled to a cooling temperature, which is lower than a melting temperature of the beverage liquid, so that the beverage liquid is partially or solidly frozen, and wherein for consumption, after the cooled storing, the beverage container is heated to a temperature between the freezing point of the beverage liquid and 0°C such that the beverage liquid melts and the at least one water ice molding remains frozen.

So how did the examiner get away with so many references to reject this new method? The flexible approach to obviousness.

Kukki’s brief set forth numerous reasons why the combination was deficient. For example, they pointed out that most of the references relied by the examiner were for making drinks in an open glass (such as a whiskey on the rocks), and that the cited art used process steps in a different order than that claimed. Kukki also argued that none of the cited art, even when combined, taught the combined approach along with the specified closing of the container after filling it with the beverage (bolded above). And even the PTAB had to agree that after considering all eight references as a whole, some “inferences” where still necessary (but obvious) to meet all claimed limitations.

In the end the PTAB went out of their way to rely on the flexible KSR inquiry and the skill and creativity of the ordinary artisan.

As pointed out by the Examiner, Moore teaches a container with a screw top closure such that it is reasonable to assume that the container will be closed and sealed, for example, to prevent spilling when a user is moving about (Ans. 3; Moore ¶¶ 15, 31, Fig. 6). One of ordinary skill would likewise readily appreciate one may close the container to store and freeze the beverage for later consumption as exemplified in Simpson (e.g., Ans. 5–6; Simpson Title (Packaging, Storing, and Vending Frozen Concentrates and the Like)). The Examiner relies upon Simpson to exemplify that it was old and well known to introduce and store a beverage concentrate in a container that has ice therein to keep beverages frosted (i.e., partially frozen) or frozen in a container with an ice seal that remains frozen, then defrosting the liquid and consuming it (Final Act. 9, Ans. 5; Simpson col. 4, ll. 15–30; col. 5, ll. 10–17; col. 10, ll. 29–37). The Examiner relies upon WR to exemplify that it was known to place ice in a container before placing the beverage therein. Indeed, as there are only two alternatives to choose from (inserting ice before or after a beverage is placed in a container), one of ordinary skill and creativity would have found the use of either alternative obvious.

In light of these disclosures, as well as other disclosures relied upon but not argued by Appellant, Appellant has not persuaded us of any reversible error in the Examiner’s determination that one of ordinary skill would have readily appreciated that ice may be inserted into a container either before or after a beverage is placed therein (such as an alcohol based beverage with a lower melting point than ice), that a closable container may then be closed to, e.g., delay consumption of a beverage, and that at least partially freezing the beverage as exemplified in Simpson may be useful for the storage of any beverage and ice combination in the Moore closable container.

While reasonable minds can differ on the outcome, it is important to realize just how far some PTAB judges will stretch the flexible KSR test and structure reasoning that breaks down the invention in such a way as to piece together reasons for rejection.

Leave a comment